Multistage Pumps

Centrifugal Multistage pumps are the pump of choice when boosting clean & low viscosity fluids and require high pressure. Multistage centrifugal pumps benefits included compact design and can be installed horizontally or vertically. Materials included cast iron, AISI 304/316 stainless steel plus exotic alloys.

Special versions include

- Series Pumping

- Low NPSH

- High Temperature

- Passivation / Coatings

- ATEX

- Reduced Footprint

- Series Pumping

- Low NPSH

- High Temperature

- Passivation / Coatings

- ATEX

- Reduced Footprint

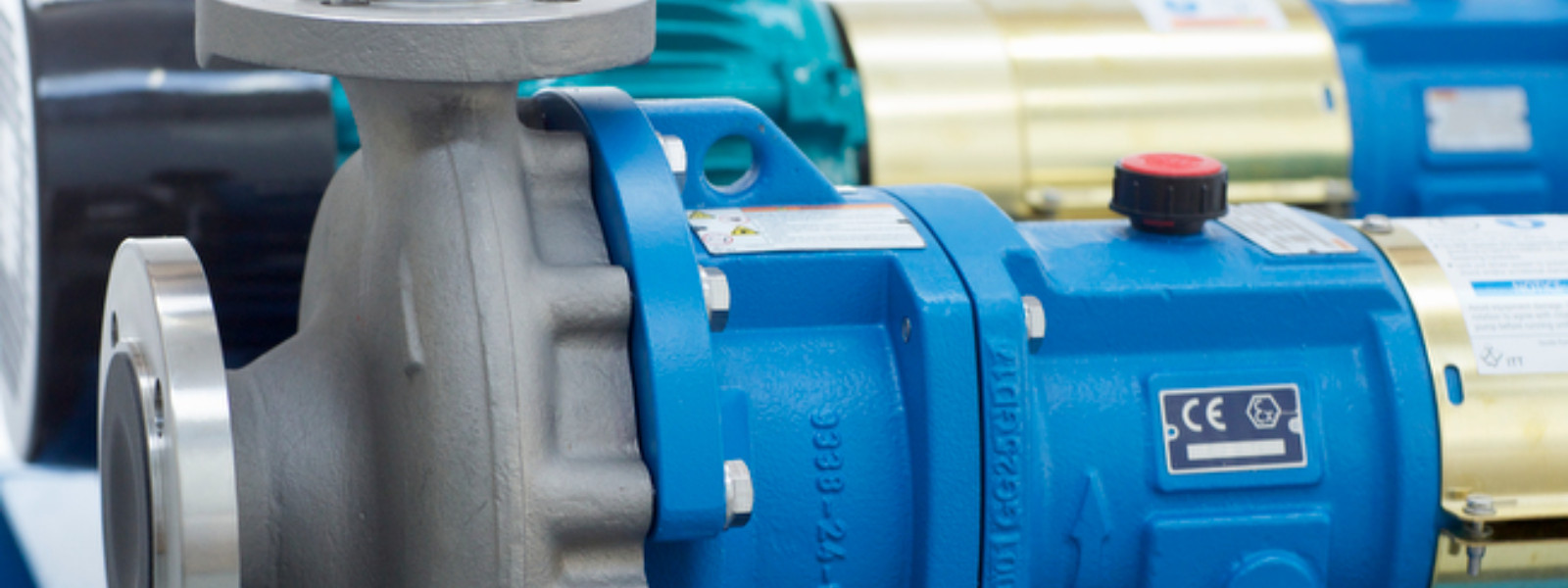

End Suction Pumps

Centrifugal End suction pumps are used in a vast range of applications within key industry due their flexibility to pump clean cold water to liquid containing solids. With three impeller types (open, semi open & closed) and vast materials options (cast iron, AISI 304/316 Stainless steel, bronze and other exotic alloys) when a products needs transferring from A to B a centrifugal end suction pump an ideal solution. Pump designs include Extended shaft, stub shaft, frame mounted and bare shaft.

Build Standards

- EN733

- ISO 2858

- ISO 5199

Self Priming Pumps

Self-priming pumps are often used where a submersible pump can’t be installed due to space restraints. Their solids handling capabilities make them a great trash pump for unclogging. An internal non return valve fitted on the suction side ensures when the pump switches off, there is sufficient liquid within prime chamber so it doesn’t dry run.

Advantages

- Suction lifts up to 7m

- Used on clean / waste water

- Automatic self-priming

- Easy maintenance